What Is Die Casting

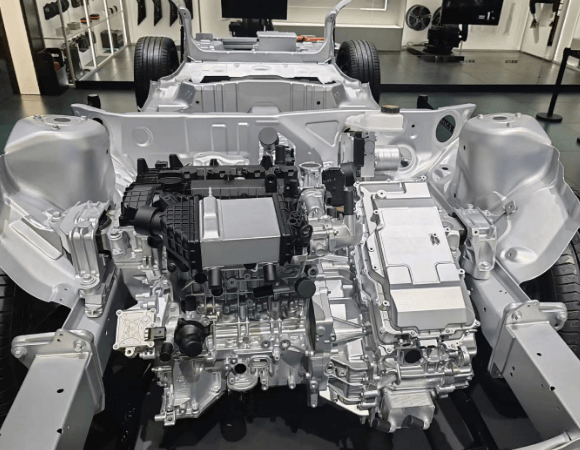

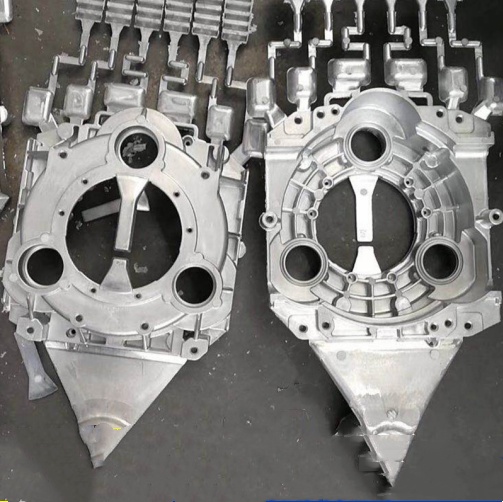

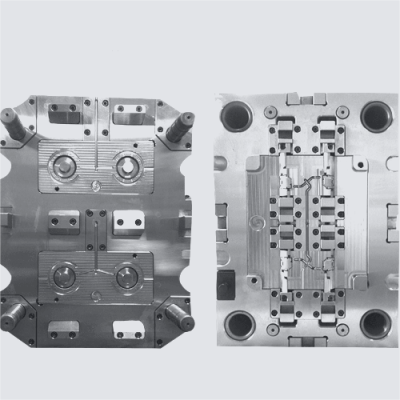

Die casting, a metal casting method involves applying high pressure to molten metal within a mold cavity. Typically crafted from robust alloys, molds resemble those used in injection molding. Materials commonly cast include zinc, copper, aluminum, magnesium, lead, tin, and their alloys. Depending on the process, machines vary between cold chamber and hot chamber die casting, with pressure capacities ranging from 400 to 4000 tons.

Die Casting Processes

Every project is unique, requiring tailored solutions. ZXP Tech offers multiple die casting processes to ensure the right method for each application.

Hot-Chamber:

Ideal for zinc, select magnesium alloys, and other low-melting metals, hot-chamber die casting is suitable for alloys that don’t corrode metal pots, cylinders, or plungers.

Cold-Chamber:

Suited for metals with higher melting points like aluminum, cold-chamber die casting involves liquefying metal and ladling it into a cold chamber, where a hydraulic plunger pushes it into the die.